I was told last night I should publish some of the mods I've done to my TR6 in the case that others may be interested, so I'll start with the Hydraulic Release bearing kit that I found from Racetorations (http://www.racetorations.co.uk).

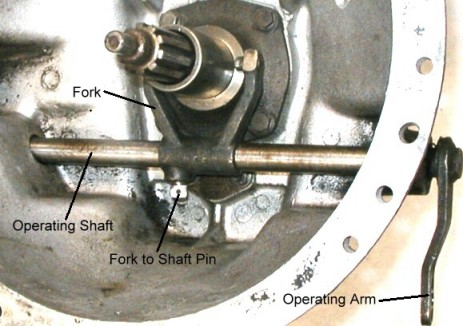

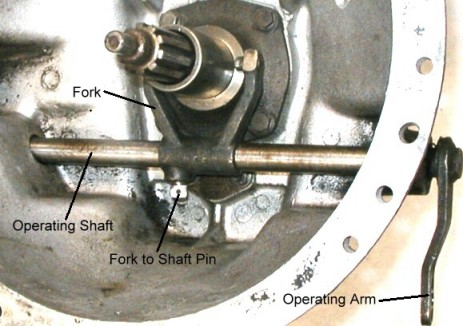

As many of us would know, the original clutch fork mechanism wasn't one of Triumph's best designs, with the pin that holds the fork on the shaft, shearing from the moment of pushing the clutch, and the fact that its not central adds another moment. So when it breaks, it doesn't completely fail, but makes the pedal only half effective.

Add to this that many owners have also had the issue of the collar that slides over the input shaft binding after many years of use due to lubricant caked with clutch dust, and the fact that the collar isn't being pushed forward and back directly along the line of the collar, but the forces imposed on it are also down by the mechanism.

Both of these issues contribute to a pretty sub-standard clutch pedal by today's standards. And if I were going to the trouble of removing my gearbox, I wanted to upgrade it. So I did!

Original setup:

The guys at Racetorations were fantastic in giving advice on how this goes together, and if you decide to do this, then certainly spend a good 10 minutes having a chat with them so you know what you're getting.

As with many aftermarket products, the unit is generic and a little work had to be done to ensure the clearances were right. Again, the ractorations guys provided excellent instruction. In my circumstance, I had to machine 5mm off the legs of the unit for it to be otherwise a bolt in unit. The bolt spacings are spot on. The only other small modification was to drill 4 holes: 2 small holes on the bell housing so that I could tie the hydraluic lines close to the inside, so there'd be no chance of the flywheel and its ringgear to come in contact, and another 2 holes to pass the lines out.

Click on a gallery image below to follow the steps.

From here, I found rubber plugs to keep the dust out from where the old shaft use to pass.

And the other last tricky bit you may want to sort out before you start is to get the correct brass connections to connect your new lines to your old lines.

A year on, and its been faultless. Good luck and happy motoring.

-Ben Lewis